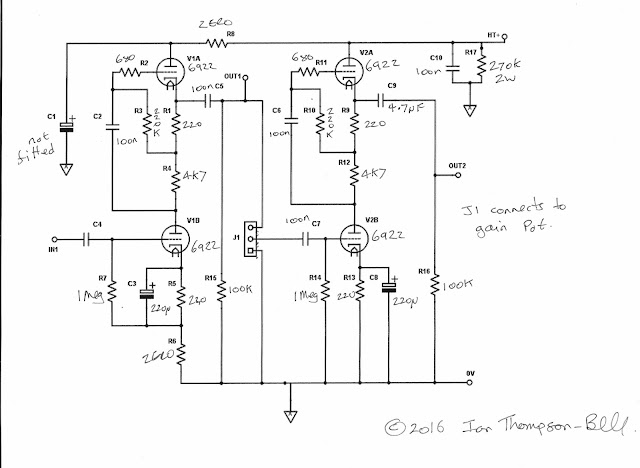

To get a better handle on the problem, let's look at the existing Eurochannel 32 way connector pin assignment.

This is the original hand drawn schematic from 2012 that defined the 32 way connector pinout. The first four pins are assigned to the mic input and the second four to the line input. Notice how the screen of each input uses two pins. The reason for this is that, at the time, I was not using a backplane PCB for the modules to plug into. Instead I was using regular connectors and wiring the backplane by hand and I found it very awkward to wire a mic cable screen to a single pin on the connector. It was much easier if I used two adjacent pins.

Next are the 48V supply and the chassis connection (which is also the 0V of the 48V). Both these use two pins each simply because they are buses and it makes hand wiring a backplane easier.

Next we have the unbalanced OUT1 and its associated 0V closely followed by the FG and FS pins. OUT1 is the output of the first amplifier in the Eurochannel design. It is often fed to an external fader and returned to the module; this is the purpose of the FS (fader slider) and FG (fader ground) pins. Not all modules or applications use this feature but it is included for those that do.

Next is a pair of pins for relay power. Most modules will need some form of auxiliary power for LEDS or relays so these two pins are often used.

Then we have four pins assigned to buses. In many cases this is too few. It allows for a stereo bus and a couple of AUX sends but this means there are none left for a solo or PFL audio bus and its associated dc bus. We could really do with twice as many bus pins.

This if followed by the main unbalanced output OUT2 and its 0V pin.

Lastly are the power pins each of which uses two pins. The HT needs tow pins so we can ensure there is always a suitable gap between these two. The heater supply needs two pins so we can easily bus the relatively high heater current along the backplane.

As you can see, this particular pin out is determined by a variety of factors, some relevant to the module and some relevant to the process of building a mixer. It has some limitations, particularly in the number of buses and there is no provision for balanced outputs simply because in the Eurochannel design they were external. There are also some non-optimum assignments from the point of view of PCB layout. For example, all the power supplies are at one end of the connector. From the point of view of PCB layout it would be better if they were near the middle of the connector. Despite its peculiarities, this bus standard has served well for over five years.

The new 6U modules being designed for the Mark 3 include output transformers so they need a way for these to be connected to the outside world. The 6U size board allows a second 32 way connector to be used. This can provide balanced outputs and additional buses but a lot of its pins are not really needed and this solution only works for 6U modules. It is no good for 3U modules.

Holger Classen has also been working on new versions of Eurochannel modules. His approach has been to retain the 3U module size but to make the module deeper. This allows output transformers to be fitted onto the PCB. In this way he can fit two complete mic pres into a single 3U module. He cannot add another 32 way connector so he proposed a new assignment of the existing 32 pins to allow for two balanced outputs. We have discussed this at length and made a few modifications until we were happy the new assignment would work for us both. Here is the new assignment of pins:

Notice first that the way each pin is referenced has changed. This reflects the actual row and column in which the pin is located. It also makes it clear that a three row connector is used but pins are only fitted in rows a and c. This implies a 0.2inch spacing between rows. Also, only even numbered pins are fitted which again indicates a 0.2inch pin spacing.

At the top is the first balanced input and its associated balanced output. Note that only the input has a shield. The balanced output output does not really need a shield pin (its cable screen can be connected at the XLR end) This pinout is duplicated at the bottom of the connector for the second balanced input and output. A chassis pin is located at both ends of the connector.

All the power pins are located about the centre of the connector. This time the 48V and its ground have only a single pin each, just like the utility power (which replaces the old relay power). Heaters and HT supply all have two pins each for the same reasons they did in the original. HT 0V is renamed AGND to more accurately reflect its purpose.

We now have a total of eight unassigned pins, and they are genuinely unassigned. Their purpose will be determined by the design of the backplane PCB. This provides a great deal of flexibility for both Holger and myself (Holger already makes his own backplane PCBs) but all backplane PCBs will have this core pinout. So the supplies and the chassis connections will be bused on all backplane PCBs. In 1 and In 2 will both be brought out to 3 pin Molex connectors in the same way as the mic and line inputs are at present. Out1 and Out 2 will both be brought out to 2 way Molex connectors just as Out1 and Out 2 are at present.

All other pins on the backplane PCB are assignable on a design by design basis. One new version of backplane PCB will bus pins 24a, 24c, 26a and 26c for use as mix buses. Pins 8a and 8c will be brought out to a 2 pin Molex as wil pins 10a and 10c. In many mixers these can be used for external unbalanced connections to faders or EQ. This version of back-lane PCB thus emulates the original Eurochannel backplane PCB. The designs of existing PCBs (Eurochannel, Twin Line Amp, Classic, EQ with gain make up etc) will be migrated to be compatible with this backplane PCB.

All new designs will adopt the new pinout and new backplane PCBs will be designed as and when the need arises.